Avoiding overtimes, project delays and schedule conflicts? It’s possible with the right resource capacity planning process. But which capacity planning strategies and tools could help you turn resource management into pure profits? Let’s find out?

What Is Capacity Planning? Meaning and Defition

Capacity planning is the strategic process of aligning available resources—such as workforce, expertise, and technology—with projected demand to ensure optimal service delivery, profitability, and client satisfaction. It involves forecasting future workload management requirements, assessing current resource availability, and implementing adjustments to prevent underutilization or overallocation of personnel.

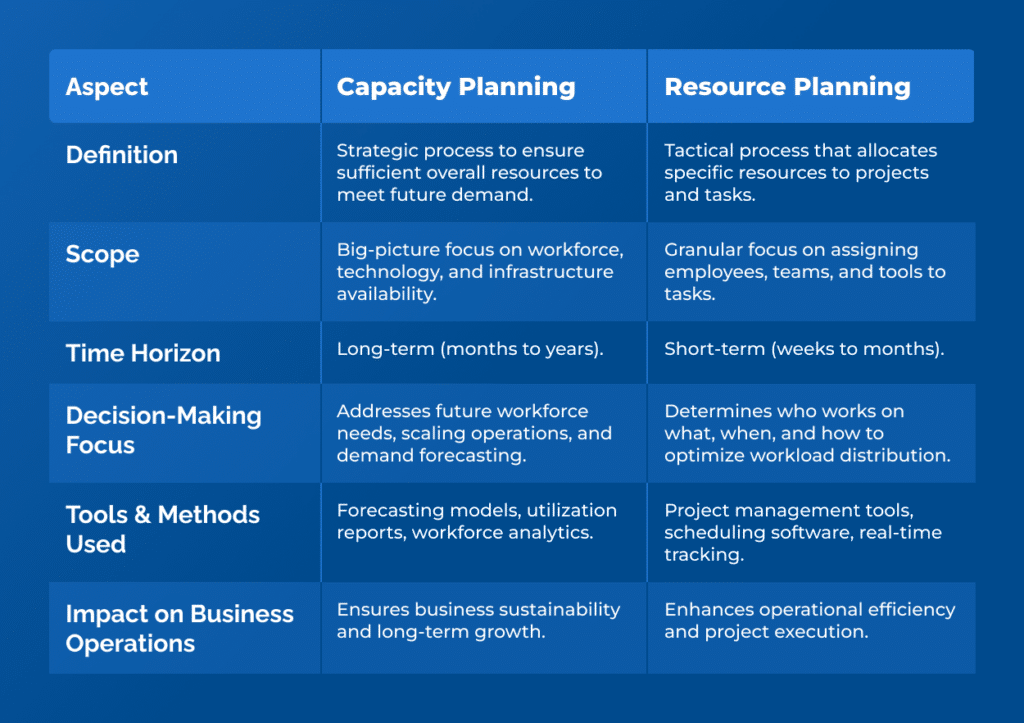

Capacity Planning vs Resource Planning – What’s The Difference?

Capacity planning and resource planning are both essential for managing workforce, resource availability, and operational efficiency in professional services firms, but they serve different purposes.

Capacity planning is a strategic, long-term process that ensures a company has sufficient overall resources to meet future demand, considering workforce, infrastructure, and technology. In contrast, resource planning is a tactical, short-term process focused on allocating specific resources—such as employees, teams, or tools—to projects and tasks based on availability and skill sets.

While capacity planning ensures business sustainability by forecasting workforce needs and scaling operations, resource planning enhances day-to-day efficiency by optimizing assignments and workload distribution in the resource pool.

Workforce Capacity Planning – What’s In It For Companies?

For professional services firms, effective capacity planning helps balance client commitments with operational efficiency, enabling proactive staffing decisions, improved project execution, and sustainable growth. By leveraging data-driven insights, firms can anticipate capacity constraints, mitigate risks, and enhance agility in responding to shifting market demands.

In short, with resource capacity planning, you can make the most of every working hour while supporting your staff as much as possible.

Capacity Planning Process – The Key To Perfect Resource Management

Effective capacity planning ensures that professional services firms can meet client demands while optimizing resources and maintaining profitability. The process involves a structured approach to forecasting, analyzing, resource allocation, and aligning capacity with business needs to ensure that maximum production capacity is used for billable activities.

Here’s what an effective capacity planning process looks like!

Step 1. Define Business Goals and Actual Demand

The first step in planning capacity is to align resource management with the firm’s overall business strategy. This includes identifying key objectives such as revenue growth, service expansion, or operational efficiency.

To ensure that no errors are made at the planning stage, firms must also analyze client demand, considering factors such as seasonality, market trends, and expected project pipelines. Understanding demand drivers helps in determining the required workforce and operational capacity while avoiding inadequate capacity planning.

Step 2: Assess Current Capacity

Before making adjustments and planning capacity for upcoming weeks and months, firms need a clear picture of their existing capacity of all their business operations. This includes evaluating workforce availability, skills, and workload distribution.

Companies should also assess their infrastructure, technology, and operational processes to identify any gaps or inefficiencies. Tools such as time-tracking software, workload analysis reports, and employee utilization rates can provide valuable insights.

An example of capacity planning report in BigTime

Step 3. Forecast Future Capacity Needs

Using historical data, market trends, and client commitments, firms should project future capacity requirements. Scenario modeling and predictive analytics can help firms estimate the impact of potential changes in demand, while revenue forecasting can expand the predictions with their financial details. Professional services firms should consider factors such as employee turnover, training periods, and project durations to create a realistic capacity forecast.

Step 4: Identify Gaps and Constraints

By comparing future demand forecasts with current capacity, firms can identify potential gaps. This could include workforce shortages, schedule conflicts, skill gaps, or inefficiencies in service delivery. Identifying these constraints early allows firms to proactively address them before they impact client satisfaction or project delivery.

Utilization management module in BigTime notifies managers about any mistakes made in allocations.

Step 5: Select the Right Capacity Planning Strategy

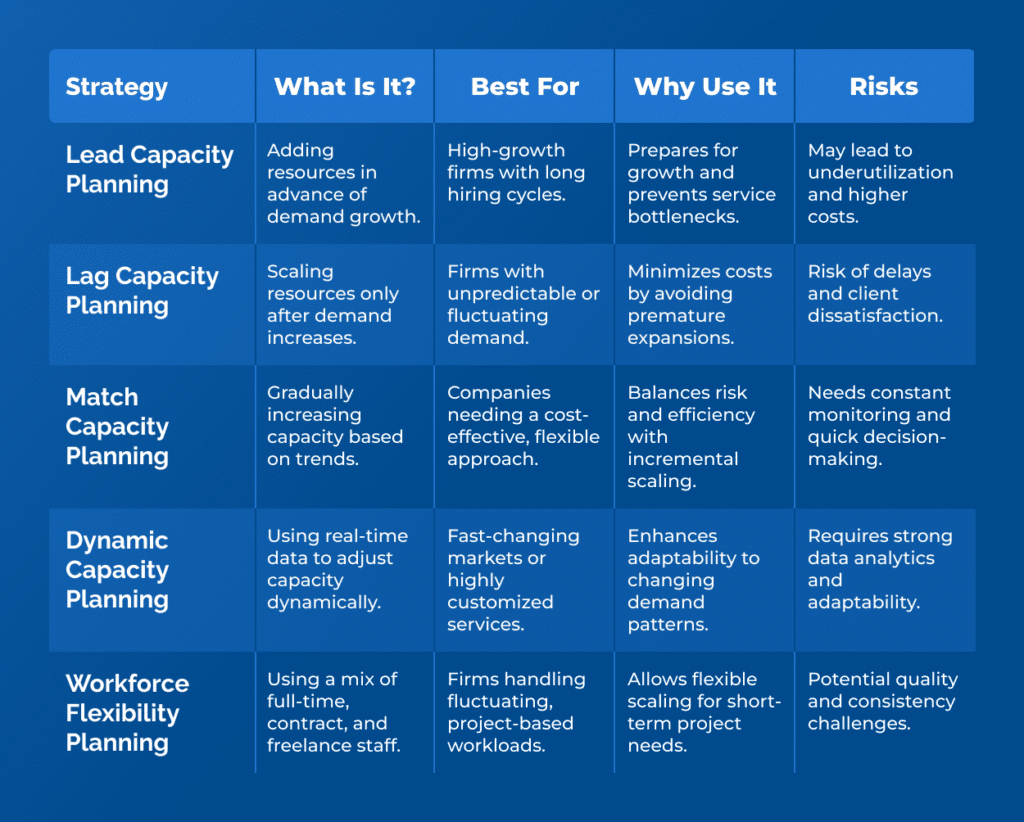

Based on the analysis, firms must choose an appropriate capacity planning strategy. Types of capacity planning strategy include:

- Lead Capacity Planning (proactively increasing capacity ahead of demand growth),

- Lag Capacity Planning (reactively adding resources as demand increases),

- Match Capacity Planning (incrementally adjusting resources based on market trends),

- Dynamic Capacity Planning (using real-time data for agile adjustments), or

- Workforce Flexibility Planning (leveraging a mix of full-time and contract workers).

The chosen strategy should align with business objectives, risk tolerance, and market conditions.

Capacity Planning Strategies Explained

Professional services companies must strategically manage their workforce and resources to meet client demands efficiently. Fortunately, they do not have to allocate resources in Excel spreadsheets. Instead, there are a few capacity planning models they can choose from.

Capacity planning strategies – comparision

Lead Strategy for Capacity Planning (Proactive Approach)

Lead capacity planning involves increasing capacity ahead of anticipated demand growth. This means hiring more staff, investing in training, expanding office space, or upgrading technology before demand actually rises instead of managing excess capacity once it is discovered.

Firms and project managers typically use lead strategy for capacity planning when market research or historical data strongly indicates sustained business growth. It is especially useful in industries where hiring and onboarding take a long time, such as legal or IT consulting, or where service quality and meeting deadlines are crucial to maintaining strong client relationships.

Lead Strategy in Planning Capacity – Pros and Cons

The primary advantage of lead capacity planning is that it minimizes service disruptions by ensuring resources are available when demand surges, even with multiple projects scheduled to start. This proactive approach enhances customer satisfaction and supports business expansion goals by positioning the company ahead of competitors and expanding team’s capacity. However, the strategy comes with risks, including higher costs from maintaining underutilized resources and the possibility of misjudging demand, leading to inefficiencies.

Lag Strategy for Capacity Planning (Reactive Approach)

Lag capacity planning takes a reactive approach, where resources are added only when demand increases. This strategy helps firms avoid unnecessary costs by ensuring that expansions are directly tied to actual needs. Lag strategy is best suited for industries where demand is uncertain or fluctuates significantly, as well as for companies that prioritize cost control and want to avoid overstaffing.

Lag Strategy in Managing Capacity in Project Management – Pros and Cons

One of the biggest advantages of lag strategy for capacity planning is its efficiency in cost management, as it prevents firms from paying for unused resources. However, lag strategy carries risks, particularly in terms of delayed service delivery, as hiring and onboarding new employees or acquiring additional resources takes time. Additionally, if existing staff must take on a heavier workload while waiting for new hires, it can lead to burnout and decreased productivity.

Match Strategy for Capacity Planning (Balanced Approach)

Match strategy planning strikes a balance between the lead and lag approaches by making incremental adjustments to capacity based on real-time data and forecasts. Instead of large-scale expansions or reductions, firms adjust their workforce or infrastructure gradually, ensuring that capacity aligns with demand without excessive risk. This strategy is particularly useful when demand trends are relatively predictable but still require some flexibility.

Match Strategy in Planning Capacity – Pros and Cons

Capacity planning process based on match strategy offers the benefit of balancing cost efficiency with service reliability, reducing the risks associated with both overstaffing and understaffing. Another advantage is that it enables agile decision-making, as firms can make adjustments based on near-term market signals rather than relying solely on long-term projections.

However, match strategy planning requires ongoing monitoring and forecasting tools to function effectively to avoid excess capacity demand. It may not be suitable for industries experiencing rapid growth, as the incremental adjustments may not scale quickly enough to meet sudden increases in demand.

Dynamic Strategy for Capacity Planning (Agile Approach)

Dynamic capacity planning takes an agile approach, continuously adjusting resources in response to real-time demand fluctuations. It relies on advanced analytics, AI, and automation to anticipate capacity needs, assess how much capacity is needed, and make quick adjustments as necessary.

This strategy is ideal for firms where demand is highly unpredictable and varies frequently, such as consulting firms managing multiple short-term projects with different staffing requirements. It is also a strong choice for companies with access to data-driven workforce management tools.

Dynamic Strategy in Resource Planning – Pros and Cons

One of the biggest advantages of dynamic capacity planning is its ability to maximize efficiency and agility. Resources can be scaled up or down quickly, ensuring that the firm remains responsive to market conditions. Additionally, this approach minimizes the risk of misallocated resources, preventing both overinvestment and shortages.

However, implementing dynamic capacity planning requires investment in technology, such as capacity planning software, and advanced forecasting capabilities. The strategy can also be complex to execute, requiring an adaptable workforce and a flexible organizational structure for a precise capacity management.

Workforce Flexibility Planning

Workforce flexibility planning focuses on using a mix of full-time employees, freelancers, contractors, and part-time workers instead of relying solely on permanent staff. This strategy allows firms to scale operations dynamically based on client demand, making it particularly effective for businesses with fluctuating workloads or specialized project needs. These types of capacity planning are commonly used by professional services firms that need on-demand expertise, such as IT consulting firms and marketing agencies.

Workforce Flexibility Planning in Resource Planning – Pros and Cons

The primary benefit of workforce flexibility planning is its scalability, as firms can easily adjust their team’s capacity based on project requirements. It is also highly cost-efficient, reducing overhead costs associated with full-time salaries and benefits. Additionally, this strategy provides access to specialized talent when needed, allowing firms to bring in experts without long-term commitments and making their resource management more adjustable.

However, relying too heavily on freelancers and contract workers can present challenges in maintaining consistent service quality in capacity planning. Additionally, a workforce composed primarily of temporary staff may impact company culture and team cohesion, making effective team capacity planning much more difficult.

Step 6: Implement Resource Adjustments to Capacity Management

The capacity planning process doesn’t end with choosing the right methods and models. Once a capacity planning strategy is selected, firms must take concrete actions to align capacity with demand. This could involve hiring new employees, upskilling existing staff, outsourcing work to contractors, or investing in automation and technology. Firms should also develop contingency plans to handle unexpected fluctuations in demand.

Step 7: Monitor and Adjust in Real Time

Workforce capacity planning is an ongoing process that requires continuous monitoring from project managers. Therefore, adjusting capacity to any unforeseen circumstances might be necessary.

Firms should track key performance indicators (KPIs) such as employee utilization rates, project completion times, and client satisfaction levels. If discrepancies arise between projected and actual capacity planning document or tool, firms must adjust their capacity plans accordingly to meet demand and avoid errors in strategic planning. Advanced resource management tools and AI-driven analytics can help in making data-driven decisions.

Step 8: Review and Optimize the Process

Regularly reviewing the resource capacity planning process and capacity strategy ensures continuous improvement. Firms should analyze past performance (including resource utilization), assess the effectiveness of their chosen strategies, and make refinements as needed – preferably in designated capacity planning tools, to avoid errors. Gathering feedback from project managers, employees, and clients can also help optimize resource allocation and improve service delivery.

Common Capacity Planning Mistakes

Overestimating an Employee’s Availability

If you plan projects without knowing that an employee’s availability is much smaller than you think (for example, they have a holiday leave planned in the middle of the project), prepare for challenges in capacity planning. Someone else will need to cover their share of working hours at the last minute, and that’s never a good way to run a project.

Mismatch Between Skill Sets and Projects

Not every specialist knows a given field well. So if you stop planning at a very general level, you might run into serious problems later if it turns out that the people you’ve assigned to the project don’t have the right skills. Capacity planning should also consider people’s skills, not just their availability!

Overestimating the Project’s Capacity

The demand in a given project can vary depending on the resource you assign to the project. A senior employee will often deliver customer requirements several times faster than a junior specialist. This, in turn, affects capacity planning and may result in forecast misinterpretations.

5 Best Practices for Planning Your Employee’s Capacity

1. Understand Your Available Capacity

Without knowing how many hours you have available to sell each month, you can’t start a meaningful conversation with a client. Moreover, once you know your available capacity, you can take on the right projects and give recruiters enough time to find resources if you’re missing any.

2. Forecast Capacity vs Demand

Capacity planning is all about the future. You have a few projects in front of you, and now you’re trying to see how they fit into the resources you’ve got. Smart capacity planning allows you to be more accurate in your predictions. And thanks to forecasting, you can develop a project resource plan in advance.

3. Track and Analyze the Skills Matrix in Real Time

While considering your available capacity, keep a close eye on the skills matrix at your company. You need to know what skillsets are available to you right now and when other competencies are going to free up soon. This information is a perfect guide for a focused sales effort or recruitment strategy.

4. Predict and Improve Overall Resource Utilization

Constant workload monitoring allows you to review historical data but also forecast employee utilization. You can quickly respond to the changing utilization by hiring additional staff or informing the sales department about resource availability so they can find projects for everyone.

5. Foresee Project Vacancies and People on the Bench

Use capacity planning to understand where your resources are going and for how long they will be locked into their projects. If you’re negotiating a new project with a client, take this information into account, and you’ll be able to easily tell whether realizing this project 2 months from now will require hiring additional resources.

The same goes for your bench — you can reduce bench time if you know that certain team members are going to finish a project soon and will be available for other projects.

Benefits of Capacity Planning

Knowing your available capacity brings many perks to your overall planning process. But the following are the biggest advantages that make capacity planning such a valuable process for professional services companies.

Here are the most important benefits of capacity planning!

Data-Driven Hiring Decisions – HR Capacity Planning

Good capacity planning brings insights into which roles you need to fill to take on a future project to meet customer demand. Thanks to this, HR teams get a clear overview of your recruitment needs and have enough time to source, recruit, and onboard new employees. That’s how capacity planning helps companies avoid resource bottlenecks in the future by monitoring the actual demand for different skills.

More Visibility for the Sales Team

Greater visibility is one of the greatest benefits of capacity planning. Monitoring current capacity offers sales reps more visibility into the production pipeline. That’s how they can learn whether there’s room for more projects within a given period and which skill sets will become available. Then, they can compare that information to customer demand and adapt their operations management to available resources.

Better Planning and Forecasting

An accurate planned capacity allows you to calculate profit forecasts because you know what projects your teams will be taking on in the near future. By including tentative projects in your planning, you can create simulations of future revenues if you end up securing the client.

Tool Capacity Planning? The Best Choice For Error-Free Plans!

To plan capacity at the level of the entire company, you need capacity planning software offered by BigTime Foresight.

BigTime Foresight is an ideal tool for capacity planning in professional services firms due to its comprehensive features that integrate resource management with financial forecasting. It enables organizations to model and forecast project profitability by selecting optimal resource plans, providing a unified view of available resources, skills, and costs, from a level of team members to company-wide overview. This holistic perspective allows firms to balance capacity and utilization effectively, ensuring that project plans align with service delivery goals.

To add to that, BigTime Foresight as a capacity planner can help you plan resources for new projects in many different scenarios thanks to intuitive forecasts and draft allocations, allowing you to meet actual demand regardless of the circumstances.Additionally, BigTime Foresight facilitates collaboration among delivery, finance, and sales teams through live reporting, enhancing decision-making processes.

BigTime bridges the gap between resources and finances with intuitive reports

The platform’s intuitive features, such as drag-and-drop scheduling and the ability to assign roles or individuals, simplify the planning process. It also offers flexibility to adjust plans as project demands evolve, allowing firms to iterate various scenarios to achieve the best outcomes.

By combining resource planning with financial insights, BigTime Foresight bridges the gap between project delivery and financial outcomes, making it a valuable tool for firms aiming to optimize capacity planning and enhance profitability.